The ZF 6HP21 is a 6-speed automatic transmission known for its mechatronic control‚ ensuring smooth shifting and efficiency. The EDS solenoid plays a key role in its operation.

1.1 Overview of the ZF 6HP21 Transmission

The ZF 6HP21 is a 6-speed automatic transmission designed for high performance and fuel efficiency. It is widely used in vehicles like BMW‚ Audi‚ and Jaguar‚ featuring advanced mechatronic control for precise gear shifting. The transmission integrates key components such as the EDS solenoid system‚ which ensures smooth torque transfer and optimal clutch pack control. Its compact design and robust construction make it reliable for various driving conditions‚ emphasizing efficiency and durability.

1.2 Importance of the EDS Solenoid in Transmission Operation

The EDS solenoid is crucial for controlling fluid pressure in the ZF 6HP21 transmission‚ ensuring precise clutch pack engagement and smooth gear shifts. It regulates torque transfer and maintains optimal transmission performance. Faulty EDS solenoids can lead to erratic shifting and diagnostic trouble codes‚ emphasizing their vital role in the mechatronic control system. Proper solenoid function is essential for reliable operation and preventing transmission failure.

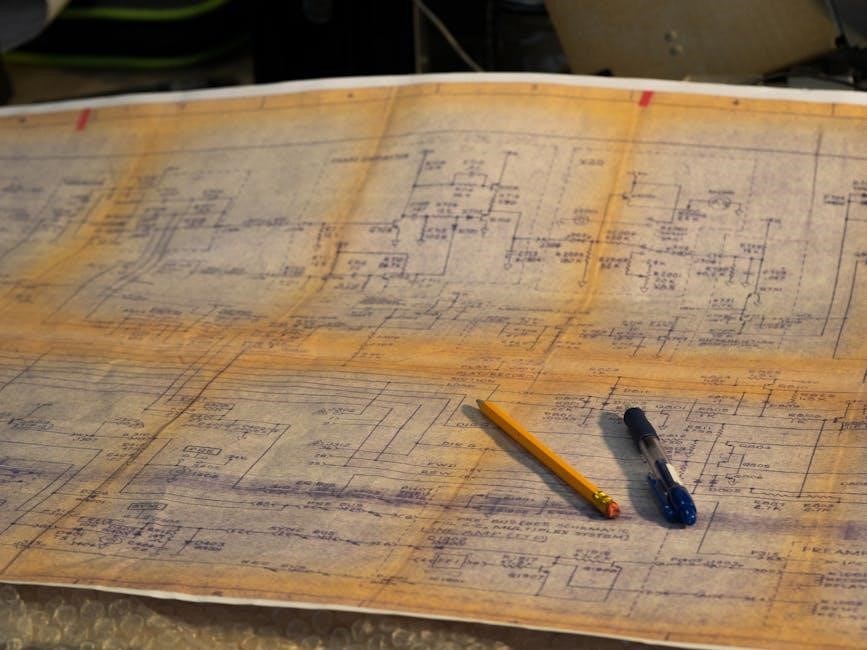

ZF 6HP21 EDS Solenoid Diagram

The ZF 6HP21 EDS solenoid diagram illustrates the mechatronic control system‚ showing component locations and wiring for EDS and MV solenoids. It provides a detailed layout of solenoid positions‚ labels‚ and connections‚ essential for diagnostics and repairs. The diagram also includes the valve body structure for reference.

2.1 Components of the EDS Solenoid System

The EDS solenoid system in the ZF 6HP21 transmission includes components like EDS1‚ EDS2‚ EDS3‚ and EDS4 solenoids‚ which control pressure and gear changes. Additionally‚ it features MV1‚ MV2‚ and MV3 solenoids for manual valve operations. The system also includes a mechatronic control unit‚ wiring harness‚ and sensors to monitor and regulate transmission functions. These components work together to ensure precise control over transmission operations.

2.2 Wiring and Circuit Schematic for EDS Solenoids

The EDS solenoid system in the ZF 6HP21 transmission is supported by a detailed wiring diagram‚ showing connections for EDS1-EDS4 and MV1-MV3 solenoids. The circuit includes a wiring harness with specific connectors‚ such as 704J for EDS4 (PWM) and 705J for MV1 (On/Off). The mechatronic unit controls these solenoids through electrical signals‚ ensuring precise pressure and gear shifts. The schematic also highlights sensor integration and troubleshooting points.

EDS Solenoid Operation and Functionality

The ZF 6HP21 transmission relies on EDS solenoids for precise control of pressure regulation and gear shifts. These solenoids operate using PWM signals from the mechatronic unit‚ ensuring smooth transitions between gears. Proper functionality is crucial for maintaining transmission performance and efficiency‚ making their operation a key focus in both repair and maintenance processes.

3.1 EDS-1‚ EDS-2‚ EDS-3‚ and EDS-4 Operations

The EDS solenoids (EDS-1 to EDS-4) in the ZF 6HP21 transmission are responsible for controlling pressure regulation and gear actuation. EDS-1 manages line pressure‚ while EDS-2 and EDS-3 regulate clutch and band application. EDS-4 typically controls the torque converter lockup. Each solenoid operates via PWM signals from the mechatronic unit‚ ensuring precise shifting and smooth power delivery. Proper synchronization of these solenoids is critical for optimal transmission performance.

3.2 Solenoid Resistance Chart and Specifications

The ZF 6HP21 transmission solenoids have specific resistance values: EDS-1‚ EDS-2‚ and EDS-4 typically range between 5-7 ohms at 20°C. Accurate measurement requires an ohmmeter with a voltage supply below 0.6V to prevent damage. These specifications ensure proper electrical operation and are crucial for diagnosing faults. Always refer to the official manual for precise values and measurement guidelines to maintain transmission performance and reliability.

Technical Service Information and Manuals

The ZF 6HP21 transmission technical service information includes detailed solenoid application charts‚ diagnostic data‚ and valve body diagrams. Official ZF service manuals provide comprehensive repair guidelines. Accessing these resources ensures accurate diagnostics and efficient repairs‚ with printable PDF diagrams available for reference.

4.1 ZF 6HP21 Repair Manual Overview

The ZF 6HP21 Repair Manual provides a comprehensive guide for transmission maintenance and repair. It includes detailed instructions for solenoid replacement‚ diagnostic troubleshooting‚ and valve body overhauls. The manual is essential for ensuring proper functionality and longevity of the transmission system.

Key sections cover solenoid application charts‚ wiring diagrams‚ and step-by-step repair procedures. Official ZF resources offer accurate and reliable information‚ making it indispensable for professionals and DIY enthusiasts alike. Access to printable PDF diagrams enhances the repair experience‚ ensuring clarity and precision in every efficient step.

4.2 Solenoid Application Chart and Diagnostic Data

The solenoid application chart provides detailed specifications for EDS-1‚ EDS-2‚ EDS-3‚ and EDS-4 solenoids‚ ensuring proper functionality. Diagnostic data includes fault codes‚ resistance values‚ and wiring diagrams for accurate troubleshooting. This resource helps identify faulty solenoids and guides repairs effectively.

Technical service bulletins and PDF manuals offer comprehensive solenoid application charts‚ enabling precise diagnostics and efficient maintenance. These tools are essential for resolving transmission issues related to solenoid performance and ensuring optimal operation.

Solenoid and Sensor Resistance Chart

The chart specifies solenoid resistance values (e.g.‚ 5.0 ohms at 20°C/68°F) and sensor diagnostics. It ensures accurate measurements for troubleshooting and maintenance of the ZF 6HP21 transmission.

5.1 EDS Solenoid Resistance Values

The EDS solenoids in the ZF 6HP21 transmission have specified resistance values‚ typically measuring 5.0 ohms at 20°C/68°F. Accurate measurement requires removing the circuit board and using an ohmmeter with a voltage supply of no more than 0.6V. This ensures reliable diagnostics and troubleshooting‚ aligning with the solenoid function chart provided in the official service manual for precise transmission maintenance and repair protocols.

5.2 Sensor Resistance and Diagnostic Procedures

Sensor resistance in the ZF 6HP21 transmission is critical for accurate diagnostics. Using a dial indicator‚ measure the snap ring groove to ensure proper alignment. For solenoid sensors‚ an ohmmeter with a voltage supply under 0.6V is recommended. Refer to the solenoid function chart and diagnostic data for precise troubleshooting. This ensures reliable verification of sensor integrity‚ maintaining optimal transmission performance and facilitating effective fault resolution.

Internal Wire Schematic and Valve Body Diagram

The ZF 6HP21 transmission features a detailed internal wiring schematic‚ showcasing the layout of EDS and MV solenoids. The Sonnax valve body diagram provides a clear visual reference for component locations and connections‚ aiding technicians in diagnosing and repairing transmission issues efficiently.

6.1 Internal Wiring Layout for EDS Solenoids

The ZF 6HP21 transmission’s internal wiring layout for EDS solenoids is meticulously designed to ensure precise control over gear shifts. The circuit integrates PWM solenoids‚ such as EDS-1‚ EDS-2‚ and EDS-3‚ each connected to specific terminals. These solenoids regulate hydraulic pressure‚ enabling smooth transmission operation. The wiring diagram outlines the connections between the mechatronic unit‚ solenoids‚ and sensors‚ providing a clear reference for troubleshooting and repairs.

Technicians can use the internal wiring schematic to trace circuits‚ verify solenoid resistance‚ and identify faults. The diagram also highlights the location of key components‚ such as the manual valve (MV) solenoids and pressure sensors. This detailed layout is essential for accurate diagnostics and ensures efficient transmission performance when properly maintained or repaired using the official service manual guidelines.

6.2 Sonnax Valve Body Diagram for ZF6HP21

The Sonnax valve body diagram for the ZF6HP21 transmission provides a detailed visual breakdown of the valve body components‚ including solenoids and pressure sensors. It also covers ZF6HP28 and ZF6HP34 units‚ making it an essential tool for technicians working on these models. The diagram clearly labels each part‚ facilitating efficient diagnostics and repairs. Additionally‚ ZIP kits are recommended for valve body overhauls‚ ensuring precise and reliable transmission performance. Always refer to the official service manual for the most accurate and up-to-date information to guarantee effective repairs and maintenance.

MV Solenoid Operation and Integration

The MV solenoids (MV1‚ MV2‚ MV3) function as manual valves‚ controlling transmission pressure and gear shifts. They integrate with EDS solenoids to ensure precise transmission operation.

7.1 MV1‚ MV2‚ and MV3 Solenoid Functions

MV1‚ MV2‚ and MV3 solenoids act as manual valves‚ controlling transmission pressure and gear shifts. MV1 regulates line pressure‚ MV2 manages shift timing‚ and MV3 controls torque converter engagement. They operate in conjunction with EDS solenoids to ensure smooth transitions and precise control. These solenoids are normally open or closed‚ depending on the transmission’s operational mode‚ and are essential for maintaining optimal performance and responsiveness.

7.2 Manual Valve (MV) vs. Solenoid-Controlled Systems

The manual valve (MV) system relies on mechanical inputs‚ while solenoid-controlled systems use electronic signals for precise control. MV systems are simpler and more durable but lack the adaptability of solenoid systems. Solenoid systems‚ like those in the ZF 6HP21‚ offer real-time adjustments for smoother shifting and better performance. This comparison highlights the evolution from mechanical to electronic control in transmission technology.

Diagnostic and Troubleshooting Guide

Identify common EDS solenoid faults like erratic control or fault codes. Measure solenoid resistance (5.0 ohms at 20°C) and ensure proper wiring connections for accurate diagnostics.

8.1 Common EDS Solenoid Fault Codes and Solutions

Common EDS solenoid fault codes include erratic control‚ high resistance‚ or circuit malfunctions. Solutions involve measuring solenoid resistance (5.0 ohms at 20°C) and checking wiring connections. Replace faulty solenoids or sensors as needed. Reset fault codes after repairs using diagnostic tools. Ensure proper solenoid operation by verifying circuit voltage and ground connections. Refer to the solenoid application chart for specific troubleshooting steps.

8.2 Measuring Techniques for Solenoid and Sensor Verification

To verify solenoid and sensor functionality‚ measure solenoid resistance (5.0 ohms at 20°C) using an ohmmeter with ≤0.6V supply. Check sensor resistance and ensure proper circuit connections. Remove the circuit board for accurate readings. Use diagnostic tools to monitor sensor outputs and solenoid activation. Verify wiring integrity and ensure no voltage drops. Compare measurements with the solenoid resistance chart for validation.

Repair and Maintenance Best Practices

Consult the ZF 6HP21 repair manual for detailed procedures. Use the solenoid resistance chart to verify specifications. Refer to the Sonnax valve body diagram for precise repairs. Always use genuine parts and follow best practices for reliable transmission performance.

9.1 Step-by-Step Replacement of Faulty Solenoids

Start by disconnecting the battery to prevent electrical shocks. Remove the valve body and locate the faulty solenoid using the EDS solenoid diagram. Use a solenoid removal tool to extract the old unit. Replace it with a genuine ZF solenoid‚ ensuring proper seating. Reinstall the valve body and reconnect electrical connectors. Check solenoid resistance to confirm it matches specifications before reassembling the transmission. Refer to the Sonnax valve body diagram for precise alignment. Always use genuine parts for reliable performance.

9.2 Tools and Resources for ZF 6HP21 Transmission Repair

Essential tools include a solenoid removal tool‚ torque wrench‚ and multimeter for verifying resistance. Refer to the official ZF 6HP21 service manual for detailed procedures. Utilize Sonnax valve body diagrams for precise repairs. Genuine ZF parts and Solenoid Application Charts ensure compatibility. Downloadable PDF manuals and diagnostic guides provide comprehensive troubleshooting support. Always use certified tools to maintain transmission integrity and performance.

PDF Manual and Diagram Resources

Access the official ZF 6HP21 service manual and printable solenoid diagrams for precise repairs. Utilize the Sonnax valve body diagram for clarity. Download PDF resources from reputable sources for detailed EDS solenoid and wiring schematics‚ ensuring accurate transmission repairs with genuine parts and updated technical specifications.

10.1 Accessing the Official ZF 6HP21 Service Manual

To access the official ZF 6HP21 service manual‚ visit ZF’s authorized dealer websites or contact their customer support. Use part numbers like S671 090 253 or 1071 766 701 to ensure authenticity. The manual provides detailed diagnostic and repair procedures‚ including EDS solenoid operation and wiring diagrams. Verify the source for authenticity to avoid counterfeit documents. Always cross-reference with the latest technical service bulletins for updates.

10.2 Printable Solenoid and EDS Diagrams for Reference

Printable solenoid and EDS diagrams for the ZF 6HP21 are available in PDF format through ZF’s official website or authorized dealers. These diagrams provide detailed layouts of solenoid locations‚ wiring‚ and valve body configurations. Use part numbers like ZF6-6R60-ZIP to ensure authenticity. Download these resources for easy reference during repairs or diagnostics‚ ensuring accurate visual guidance for solenoid replacement and system troubleshooting.

Case Studies and Real-World Applications

Case studies highlight successful ZF 6HP21 repairs using solenoid diagrams‚ showcasing troubleshooting of faulty EDS solenoids and lessons learned by technicians.

11.1 Successful Repairs Using the Solenoid Diagram

Technicians have successfully repaired ZF 6HP21 transmissions by referencing solenoid diagrams in PDF manuals. These diagrams helped identify faulty solenoids‚ such as EDS-1 or MV1‚ enabling precise replacements. Real-world examples include correcting erratic shifting caused by worn solenoids and resolving EDS fault codes. The detailed layouts ensured accurate troubleshooting‚ restoring transmission performance efficiently. Such cases underscore the diagram’s value in diagnosing and repairing complex transmission issues.

11.2 Lessons Learned from EDS Solenoid Replacements

Lessons from EDS solenoid replacements highlight the importance of accurate diagrams and proper diagnostic tools. Common issues include worn solenoids causing erratic shifting and EDS fault codes. Replacing faulty solenoids like EDS-1 or MV1 requires precise alignment with the valve body. Using official PDF manuals ensures correct installation‚ preventing further damage. These experiences emphasize the need for adherence to manufacturer specifications for reliable transmission performance.

12.1 Summary of Key Points

The ZF 6HP21 transmission’s EDS solenoid system is crucial for smooth shifting and efficiency. Key aspects include the solenoid’s role in electronic control‚ diagnostic procedures using resistance charts‚ and the availability of detailed repair manuals. Staying updated with the latest technical service bulletins and using genuine parts are essential for maintaining performance and addressing common issues effectively.

12.2 Importance of Staying Updated with Technical Service Bulletins

Staying updated with technical service bulletins ensures access to the latest diagnostic procedures‚ repair solutions‚ and part updates for the ZF 6HP21 transmission. These bulletins often address common issues like erratic EDS solenoid control and fault codes. Regular updates help prevent recurring problems and ensure compliance with manufacturer-recommended practices. Accessing official ZF service manuals and printable diagrams is crucial for accurate repairs and maintaining transmission efficiency. Continuous support through TSBs is vital for long-term reliability and performance optimization.